We provide multimeter calibration for organizations where inaccurate electrical measurements create regulatory risk, production delays, or safety hazards. When your quality team depends on precise voltage, current, and resistance readings to release product or clear equipment for use, measurement drift isn’t just inconvenient—it’s a compliance gap waiting to be found.

Our laboratory provides both NIST traceable and ISO 17025 accredited multimeter calibration services. We test your equipment against reference standards that meet federal and international standards, then provide the detailed certificates your auditors expect to see. Send equipment to our climate-controlled lab for testing, or we can accommodate on-site service when facility constraints require it.

After 50 years calibrating electrical test equipment, we understand what’s actually at stake: passing audits, maintaining production schedules, and proving your measurements are defensible.

Multimeters We Calibrate

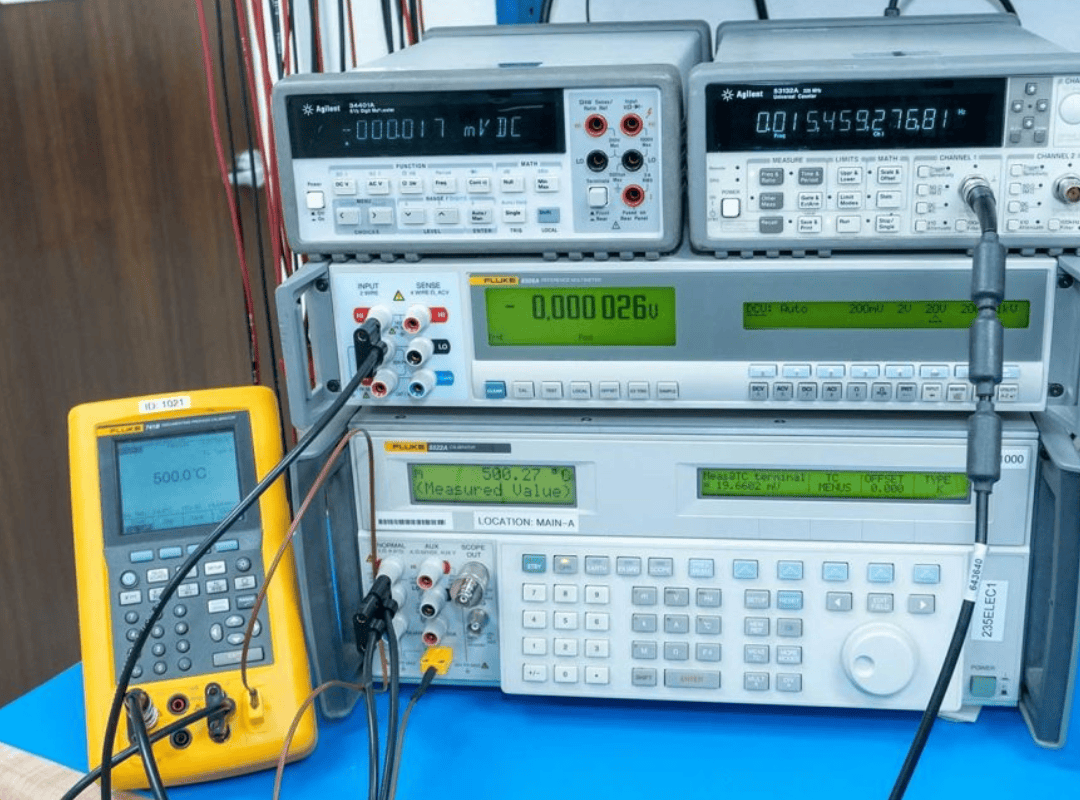

We calibrate digital multimeters, analog meters, and specialized electrical testing instruments across all accuracy classes and measurement ranges. Our capabilities cover the equipment quality managers actually use—from handheld field meters to benchtop precision instruments.

Instruments, including:

- Handheld digital multimeters

- Desktop multimeters

- Current clamp meters

- Data loggers

- Electrical testing instruments

- Special multimeters and measuring kits

- Megohmmeters

Brands we calibrate include:

- Fluke

- Agilent

- Tektronix

- Keithley

- Amprobe

- Extech Instruments

- BK Precision

- Instek

- Yokogawa

- Craftsman

- Tenma

Measurement parameters tested:

- AC voltage & DC voltage

- AC current & DC current

- Resistance and capacitance

- Conductance

- Frequency and inductance

- Temperature

- Continuity testing

- Diode testing

Whether you’re calibrating a basic troubleshooting meter or a precision instrument used for product release testing, we have the reference standards and technical capability to certify it.

Industries Served Since 1976:

Multimeters are used across regulated industries where measurement accuracy directly affects product quality, worker safety, and regulatory compliance. We provide calibration services to organizations that must document measurement traceability for audits and quality systems.

Industries relying on precision-calibrated multimeters:

- Electronics Research & Manufacturing

- Production & Maintenance Departments

- Automotive

- Energy, Utilities, & Renewables

- Chemical processing and petrochemical facilities

- Aerospace and aviation

- Medical device manufacturing

- Universities and research institutions

Why Choose Allometrics for Multimeter Calibration

ISO 17025 Accreditation You Can Verify

NIST Traceability on Every Certificate

Your calibration certificates document the complete measurement chain – from your multimeter to NIST traceable standards. This traceability withstands regulatory scrutiny. [3]

50+ Years Calibrating Electrical Test Equipment

Since 1976, we’ve calibrated measurement instruments for organizations that face audits, manage tight production tolerances, and answer to regulatory bodies. Therefore, we understand the documentation requirements, turnaround pressures, and accuracy demands you face.

Allometrics Multimeter Calibration Process

What is Multimeter Calibration?

Multimeter calibration compares your instrument’s measurements against known reference standards traceable to NIST. We apply precise input values across your meter’s measurement ranges – voltage, current, resistance, frequency – and record how your instrument responds. If readings fall outside specified tolerances, we document the deviation and can repair on approval. You receive certificates showing measurement performance before and after any adjustments.

Benefits of Regular Multimeter Calibration

Regular calibration catches measurement drift before it affects your operations. Scheduled testing identifies accuracy changes while equipment is still usable, preventing failed audits, questionable product releases, and production delays from emergency calibration needs. Documented calibration history demonstrates measurement control when regulators or customers audit your quality systems.

Risks of Neglecting Multimeter Calibration

Uncalibrated multimeters create compliance gaps that auditors will find. Equipment drifts out of tolerance while still displaying normal-looking readings, leaving you unable to prove measurements were valid when you released product or cleared equipment for use. Missing calibration records often trigger expanded audit scrutiny of your entire quality system – corrective actions that cost far more than preventive calibration. Worse, uncalibrated meters lead to costly decisions: scrapping good product, removing functional equipment from service, or releasing defective product because your test equipment said it passed.

Get Your Multimeters Calibrated By Allometrics Today

Laboratory Service for Accurate Results

Send your multimeters to our laboratory for calibration against NIST traceable reference standards. Standard turnaround is 7-10 business days for most instruments, with expedited 48-hour service available when audit deadlines or production schedules demand faster turnaround.

Field Service When You Need It

We can perform on-site calibration when equipment size, quantity, or facility requirements make shipping impractical. Our technicians bring calibrated reference standards to your location and provide the same documentation quality as laboratory service.

Nationwide Coverage

We serve regulated industries across the United States. Whether you operate a single facility or manage calibration programs across multiple sites, we provide consistent service and documentation that satisfies your quality system requirements.

Contact Information:

Allometrics

1425 Atlantis Dr Suite B

Webster, TX 77598

(281) 474-3329

1425 Atlantis Dr Suite B

Webster, TX 77598

(281) 474-3329

FAQ: Answers to Your Multimeter Calibration Questions

Resources

- https://a2la.org/accreditation/calibration/

- https://www.iso.org/ISO-IEC-17025-testing-and-calibration-laboratories.html

- https://www.nist.gov/programs-projects/measurement-services-srms-and-calibrations

We’ll be happy to assist you!

- Calibration and Certification

- Service Inquiries

- Equipment Sales

Based in Texas, Allometrics can help with calibrations across the United States and beyond.