Balance Types We Calibrate

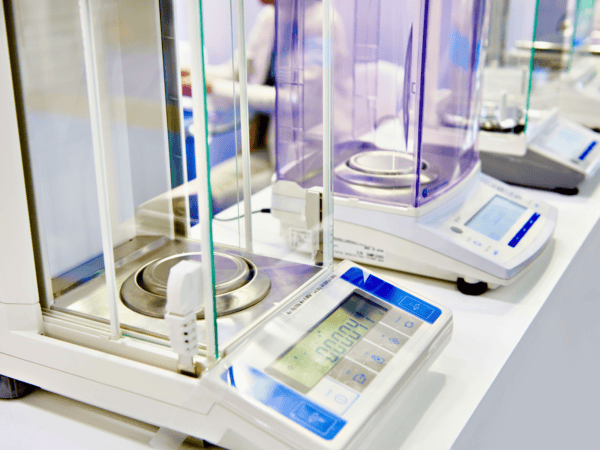

Analytical and Laboratory Balances:

- Analytical balances (4-place, 5-place readability)

- Semi-micro balances for standard preparation

- Micro and ultra-micro balances for pharmaceutical testing

- Top-loader and precision balances for general laboratory use

- Moisture balances including Sartorius Mark 3 systems

Specialized Balance Equipment:

- Explosion-proof balances for hazardous environments

- Counting balances for inventory and production control

Major Brands We Service:

Industries That Rely on Our Balance Calibration Expertise

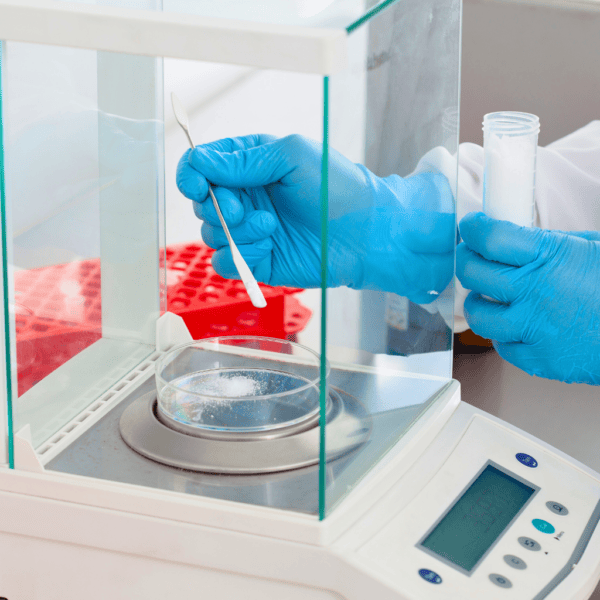

- Pharmaceutical & Biotechnology: Drug formulation, quality control testing, and research work require micro and analytical balances with documented traceability. We provide calibration services that support FDA compliance requirements with the audit-ready paperwork your quality systems need. [1]

- Chemical & Petrochemical: From analytical labs to production QC environments, chemical processing facilities depend on accurate balance calibration for formulation work, quality control, and environmental testing.

- Food & Beverage Processing: Ingredient measurement, nutritional analysis, and quality control testing require precision balances calibrated to support food safety compliance and consistent product quality.

- Manufacturing & Industrial: Raw material inspection, production quality checks, and finished product testing across manufacturing operations. Our calibration services reduce measurement uncertainty and prevent production delays.

- Research & Development: Universities, government labs, and private research facilities doing analytical work that demands ISO 17025 accredited services and strict measurement traceability.

- Environmental & Testing Laboratories: Air quality monitoring, water testing, and soil analysis where accurate balance measurements support environmental regulatory compliance.

Production Quality Control Laboratories:

Why Quality Managers Trust Allometrics for Balance Calibration

A2LA ISO 17025 Accreditation + Over 50 Years of Excellence Since 1976, we’ve delivered calibration services that meet the highest international standards for technical competence and quality management. Our ISO 17025 accreditation through A2LA provides the independent verification auditors require. [2] Our decades of experience give you confidence in our reliability and measurement expertise.

Audit-Ready Documentation That Stands Up to Inspection Every calibration includes detailed certificates with complete measurement data, traceability statements, and calibration conditions. Our documentation satisfies regulatory requirements and eliminates the stress that comes with audit season. No gaps, no questions, no findings.

Nationwide Consistency for Multi-Facility Operations Managing calibration across multiple locations shouldn’t mean juggling vendors with different results. We deliver uniform service quality, standardized documentation, and centralized program management whether you operate one lab or twenty facilities. One partner, one standard, complete visibility.

Technical Expertise Across All Balance Types Our technicians understand the unique calibration requirements of micro, analytical, precision, and moisture balances. We service equipment from all major manufacturers with proper reference standards and environmental controls that ensure accurate, defensible measurements.

Why Do I Need Balance Calibration?

Benefits of Professional Balance Calibration

- Ensures measurement accuracy for product quality decisions, formulation work, and analytical testing

- Prevents costly errors from incorrect measurements that lead to failed batches and material waste

- Provides audit-ready documentation that satisfies regulatory requirements and eliminates compliance stress

- Extends equipment lifespan through early detection of drift or mechanical issues before they become failures

- Builds confidence in your data so quality teams can make important decisions with certainty

- Reduces operational risk by maintaining consistent measurement standards across your facility

Risks of Neglecting Balance Calibration

- Measurement drift goes undetected until serious problems emerge in production or audits

- Failed regulatory inspections from missing calibration records or poor documentation

- Product quality issues including out-of-specification batches, recalls, and rejected materials

- Increased costs from premature equipment replacement, regulatory penalties, and wasted materials

- Lost confidence in quality systems requiring time-consuming investigations when results seem questionable

- Deeper regulatory scrutiny as calibration gaps suggest bigger quality problems to inspectors

Schedule Your Balance Calibration Service

FAQ: Your Balance Calibration Questions Answered

- https://www.fda.gov/drugs/guidances-drugs/questions-and-answers-current-good-manufacturing-practice-requirements-equipment

- https://a2la.org/accreditation/calibration/

- https://www.nist.gov/nist-quality-system

- Calibration and Certification

- Service Inquiries

- Equipment Sales