What is Biosafety Cabinet Certification?

Biological Safety Cabinets We Certify

Cabinet Classifications:

- Class I Biological Safety Cabinets

- Class II Type A1, A2, B1, B2, C1 Cabinets

- Class III Maximum Containment Systems

- Specialty Cytotoxic Drug Preparation Cabinets

We Service All Major Manufacturers Including:

- Thermo Fisher Scientific

- Baker Company

- ESCO Biological Safety Cabinets

- Labconco Corporation

- NuAire Biological Safety Cabinets

- Germfree Laboratories

- and more!

Our technicians bring the technical expertise to service cabinets from other major manufacturers as well, with experience across brands commonly found in pharmaceutical, research, and healthcare facilities.

Specialized Applications

- Pharmaceutical Cleanrooms Requiring cGMP Compliance

- Hospital Sterile Compounding Pharmacies

- University and Independent Research Laboratories

- Compounding Pharmacies Following USP <797> and USP <800> Standards

- Biotechnology And Life Sciences Facilities

- Research Laboratory Containment

- Clinical Diagnostic Laboratories

- Aviation Industry Testing Facilities

- Government Research Institutions

Whether you have one cabinet in a community pharmacy or dozens of units across multiple pharmaceutical facilities, we use the same testing methods and provide the same quality documentation that meets all requirements.

Industries That Depend on Our Biosafety Cabinet Certification

Labs across many different fields rely on our certification services to stay in compliance and protect their work. We understand the special rules and demands of each industry we work with, including:

Pharmaceutical and Biotechnology Pharmaceutical manufacturers and biotech companies face stringent FDA oversight and cGMP requirements. Our certification documentation provides the traceability and measurement accuracy needed to pass inspections and keep operations running

Healthcare and Hospital Systems Hospital pharmacies and clinical laboratories depend on properly functioning biosafety cabinets for patient safety and regulatory compliance. Our certification services support facilities preparing sterile preparations and handling biological materials under USP standards.

Research and Education Universities, research institutes, and government labs need certified cabinets to meet grant requirements and protect personnel. We work with facilities where equipment downtime interrupts important research schedules.

Compounding Pharmacies Independent and specialty compounding pharmacies must maintain USP <797> and USP <800> compliance for state board inspections. Our certification helps demonstrate proper environmental controls for sterile and hazardous drug compounding operations.

Why Quality Managers Choose Allometrics for Biosafety Cabinet Certification

NSF/ANSI 49 Accreditation and ISO 17025 Accreditation When You Need It

Over Five Decades of Controlled Environment Expertise

Traceable to NIST Testing Standards

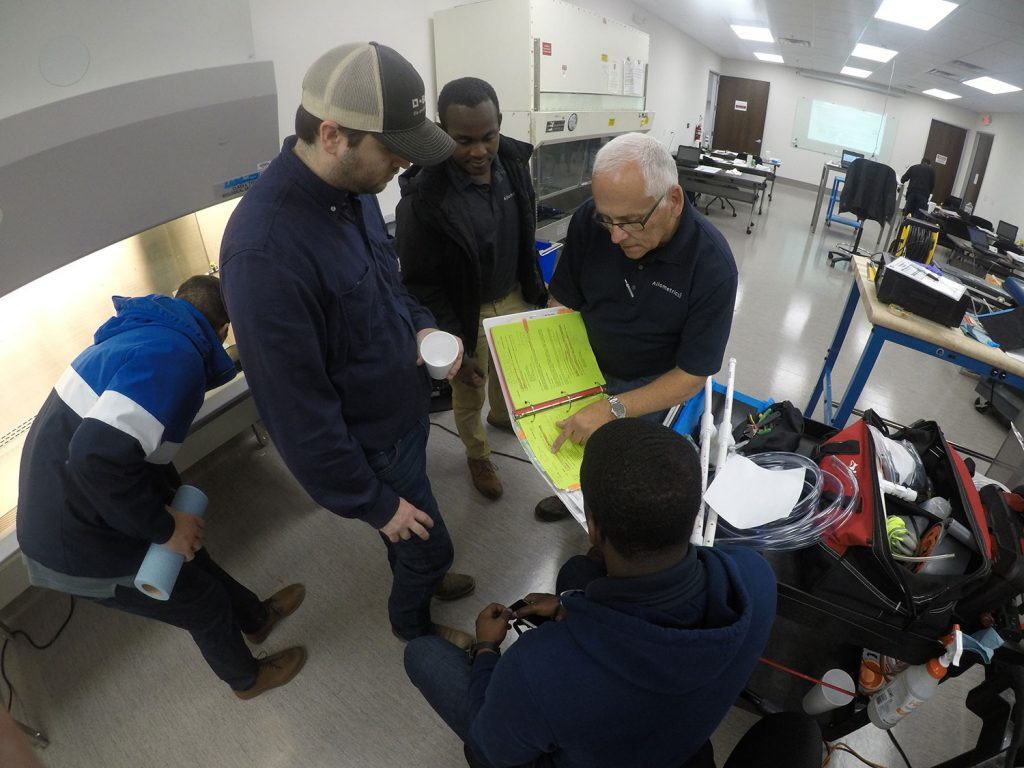

The Experts Who Train the Experts

Comprehensive Documentation When You Need It

Nationwide Service with Consistent Quality

Why Choose Allometrics Over Other Providers?

| Feature | Allometrics | Typical Provider |

| Technician Credentials | Guaranteed NSF/ANSI 49 Field Certifier when required | Varies, often unspecified |

| Laboratory Accreditation | ISO 17025 Accredited | Vast majority are not accredited |

| Measurement Traceability | Traceable to NIST | May use non-traceable standards |

| Standard Turnaround | 5-10 business days | 2-3 weeks |

| Expedited Available | 48 hours | Limited availability |

| Documentation Quality | Audit-ready, inspector-approved format | Basic compliance reports |

| ASAP Program | Proactive compliance management | Not available |

| Experience | Since 1976 (50 years) | Varies |

| Audit Acceptance Rate | 100% documentation acceptance | Not disclosed |

Available Testing Protocols:

Airflow Velocity Profile – Multi-point velocity measurements traceable to NIST across work surface with environmental compensation

Inflow and Downflow Velocity Testing – Containment barrier verification ensuring proper air balance

Smoke Pattern Test – Visual airflow pattern analysis and documentation

Viable and Non-Viable Particle Count – Environmental contamination assessment verifying ISO Class 5 air cleanliness

HEPA Filter Leak Test – Filter integrity and seal effectiveness verification

Noise Level Measurement – Operational sound level documentation

Light Intensity Test – Work surface illumination verification

UV Light Test – Germicidal lamp effectiveness (when applicable)

Electrical Safety Test – Ground fault and electrical system safety

Vibration Testing – Mechanical stability and operational smoothness

Alarm Verification – Safety system functionality verification (Class 2 Type B1/B2)

Benefits of Regular Biosafety Cabinet Certification

Regulatory Compliance and Audit Confidence Documented certification records from an accredited laboratory satisfy FDA, State Boards of Pharmacy, and accreditation body requirements. When auditors request equipment qualification documentation, you present comprehensive test results—not assumptions about cabinet performance. [2]

Personnel and Product Protection Certified cabinets provide verified containment and sterile conditions. You have documented proof that airflow velocities and HEPA filtration meet protective standards instead of just trusting indicator lights.

Early Problem Detection and Operational Continuity Regular certification identifies declining performance before complete failure. Gradual filter loading, motor wear, or seal deterioration shows up in test measurements. This allows for planned maintenance rather than emergency shutdowns during critical operations.

Risks of Neglecting Biosafety Cabinet Certification

Regulatory Violations Operating uncertified cabinets creates compliance violations. FDA inspections, state board audits, and accreditation reviews identify these as major problems—potentially stopping operations or triggering warning letters.

Personnel and Product Risk Failed containment without documented testing puts lab workers at risk and contaminates sterile preparations. Inadequate cabinet performance ruins research samples and invalidates experimental results.

Emergency Response Costs Discovering certification gaps during audits or after equipment failure forces emergency service calls, expedited repairs, and operational shutdowns that cost significantly more than planned certification.

Schedule Your Biosafety Cabinet Certification Today

What to Expect

Take the Next Step:

Request Your Free Quote – Contact our calibration experts at (281) 474-3329 for a customized estimate based on your specific equipment and requirements

Schedule Your Service – Choose from convenient mail-in, onsite, or in-lab calibration options that work with your production schedule

Access Your Records Online – View all calibration certificates and manage your instrument history through our secure web portal

- https://www.nsf.org/lab-testing/biosafety-cabinetry/biosafety-cabinet-certification

- https://www.fda.gov/media/88905/download

- Calibration and Certification

- Service Inquiries

- Equipment Sales